Thursday, May 25, 2006

Tuesday, May 23, 2006

Friday, May 12, 2006

Thursday, May 11, 2006

Tuesday, May 09, 2006

More space at Konstfack

Hi!

I have now booked two studios for the prefabrication week additional to the workshop presented earlier (pic 1). They are both some 7x8 m and are next to each other. The "bottle neck" transportationvise is the door (pic 2). It measures W 1.9m, H 2.4m. The passage from the workshop/loading bridge to the studios is about 20m and is min 1.9m wide.

/Teo

I have now booked two studios for the prefabrication week additional to the workshop presented earlier (pic 1). They are both some 7x8 m and are next to each other. The "bottle neck" transportationvise is the door (pic 2). It measures W 1.9m, H 2.4m. The passage from the workshop/loading bridge to the studios is about 20m and is min 1.9m wide.

/Teo

Friday, May 05, 2006

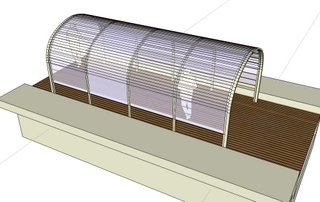

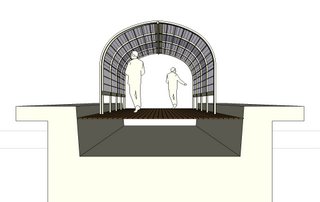

Konstfack outdoor area shelter

Hej,

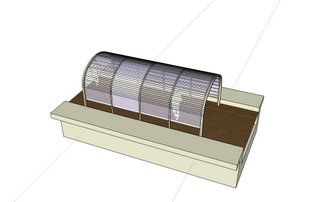

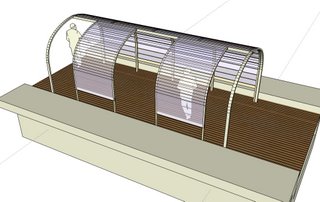

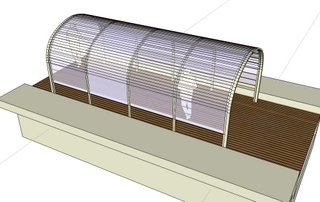

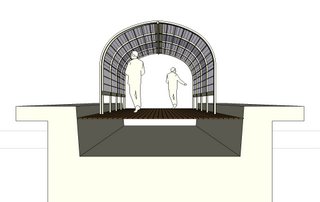

here are some infos on the shelter we thought of developing.

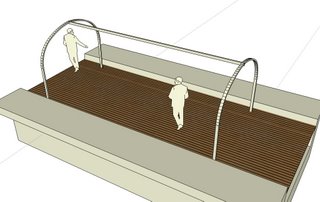

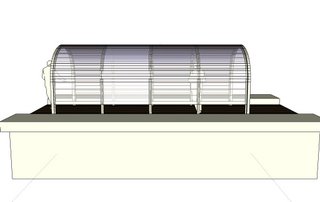

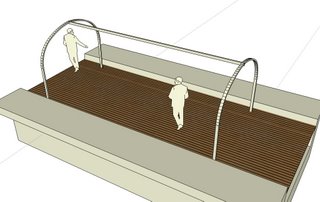

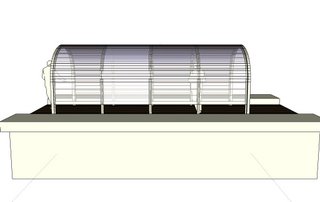

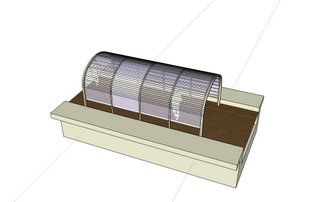

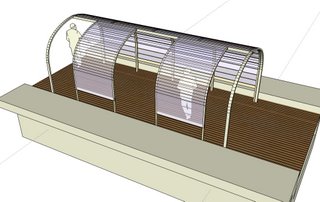

We’re aiming to realize a skeleton that would take 5 to 10 minutes to erect (pic 1). This skeleton will support a series of arched components that will hook simply over the top beam. Each component has a wood frame and will have a “skin” of a material that will provide shelter to weather. We’re deciding in these days what kind of material we could use for the skin. Yesterday during the phone conference you mentioned a textile company that would sponsor the project. Could you give us more details about it? Would they sponsor only with a specific textile or would we get the chance to chose from their range?

To make the shelter cope with the movement of the houses, we need to know how often you think your houses would move along the bridge so that we can factor this in the design.

Hej då!

The Konstfack team.

here are some infos on the shelter we thought of developing.

We’re aiming to realize a skeleton that would take 5 to 10 minutes to erect (pic 1). This skeleton will support a series of arched components that will hook simply over the top beam. Each component has a wood frame and will have a “skin” of a material that will provide shelter to weather. We’re deciding in these days what kind of material we could use for the skin. Yesterday during the phone conference you mentioned a textile company that would sponsor the project. Could you give us more details about it? Would they sponsor only with a specific textile or would we get the chance to chose from their range?

To make the shelter cope with the movement of the houses, we need to know how often you think your houses would move along the bridge so that we can factor this in the design.

Hej då!

The Konstfack team.

Konstfack products sketches

Hej everybody,

here are some 3d and sketches of the products we're developing. As you already know our project is rather conceptual, based on developing outdoor products keeping them as analogue and simple as possible, and following our initial discussions on how outdoor cooking and living is a complete different experience from cooking indoors. Although we go on with this conceptual side we definitely want our prototypes to be working for Hallefors, so this is obviously taking us a lot of time with the engineering and functional development. As said yesterday during the conference call, we're realizing this line of products so that they can be used independently of each other, as nowadays camping products do. We're NOT developing a traditional high-functionality "one piece" kitchen, instead our products can stand on any flat surface.

First of all, the stove, the product that we've been mostly working on, due to all the engineering complications and legal matters. We're keeping on working back and forth with Primus on it, to ensure it would still be a functional product. In the bigger pictures you see one of our latest design, while in the collage you can see some of the other developments we've also been working on.

The inner part with the burner measures approx. 7 cm, the cross is around 20*20 cm. A gas tube will connect this stove to the gas bottle. We're working on a way to connect more stoves to the same gas bottle, in order to be able to cook bigger meals too.

Regarding the lighting we've been developing products that would take a step away from the way outdoors lights are developed nowadays. We decided to use the formal language of classic indoors lights in order to give a strong recognition of the function and the way the lamp has to be used, and play with the displacement of this language moved in a outdoor context.

The ambient light will be probably 100 to around 130 cm high. We're deciding between two versions, both using the same kind of light-source: gas lighting with mantle incandescence reaction, to give a light with the highest performance possible. One version would have the gas bottle in the base of the lamp and the gas light inside the shade, while the second one would contain the gas bottle directly hidden inside the shade too, to enhance the connection with traditional indoors lamps. We're working on the way to light on and off the lamp and control the amount of light given, experimenting the most analogical solutions.

There will be also a table lamp, using also the gas-mantle technology.

About the sink we've developed a product that can be used in places where main water is available (not the case of Hallefors) with a particular kind of clip that can be probably mounted on any kind of bucket. We want to preserve the typology of the bucket. The main focus is to turn any bucket into a sink, so we're concentrating on how the tap connects connects to the sink. Whether there is no running water, the bucket can be used in its traditional way (eg. taking water from the river). In the images you can see some of the clips we've been working on.

The table is a simple trestle construction. The table top is a scaled up version of a chopping board. We're realizing also a table cloth in glass-fiber that will be used for cooking instead of eating on it: the material characteristics make it perfect for using it as a base for the burner, to ensure a perfect isolation with the table surface. The measures will be around 80*120 cm and around 80 cm high. We'll discuss on the eventuality of having add-on wheels to the table legs, but we''d like to get the exact measures of the rails you're planning to build for the houses

If you think of using some of these products directly for the wet unit it's fine for us, but you'll have to keep in mind that, although working, they may not have the same kind of functionalities of traditional indoors equipments, because of the fact they're for an outdoor use and for the conceptual twist we decided to give them.

I'll post as soon as possible infos on the shelter. One of my colleagues that focused on the development of the shelter is at his job this morning. As soon as he'll get free we'll post you some material.

If you have any question don't hesitate to mail us or post questions on the blog!

Let's keep in touch for the monday conference,

All the best,

Hej då :)

Andrea & the Konstfack team.

here are some 3d and sketches of the products we're developing. As you already know our project is rather conceptual, based on developing outdoor products keeping them as analogue and simple as possible, and following our initial discussions on how outdoor cooking and living is a complete different experience from cooking indoors. Although we go on with this conceptual side we definitely want our prototypes to be working for Hallefors, so this is obviously taking us a lot of time with the engineering and functional development. As said yesterday during the conference call, we're realizing this line of products so that they can be used independently of each other, as nowadays camping products do. We're NOT developing a traditional high-functionality "one piece" kitchen, instead our products can stand on any flat surface.

First of all, the stove, the product that we've been mostly working on, due to all the engineering complications and legal matters. We're keeping on working back and forth with Primus on it, to ensure it would still be a functional product. In the bigger pictures you see one of our latest design, while in the collage you can see some of the other developments we've also been working on.

The inner part with the burner measures approx. 7 cm, the cross is around 20*20 cm. A gas tube will connect this stove to the gas bottle. We're working on a way to connect more stoves to the same gas bottle, in order to be able to cook bigger meals too.

Regarding the lighting we've been developing products that would take a step away from the way outdoors lights are developed nowadays. We decided to use the formal language of classic indoors lights in order to give a strong recognition of the function and the way the lamp has to be used, and play with the displacement of this language moved in a outdoor context.

The ambient light will be probably 100 to around 130 cm high. We're deciding between two versions, both using the same kind of light-source: gas lighting with mantle incandescence reaction, to give a light with the highest performance possible. One version would have the gas bottle in the base of the lamp and the gas light inside the shade, while the second one would contain the gas bottle directly hidden inside the shade too, to enhance the connection with traditional indoors lamps. We're working on the way to light on and off the lamp and control the amount of light given, experimenting the most analogical solutions.

There will be also a table lamp, using also the gas-mantle technology.

About the sink we've developed a product that can be used in places where main water is available (not the case of Hallefors) with a particular kind of clip that can be probably mounted on any kind of bucket. We want to preserve the typology of the bucket. The main focus is to turn any bucket into a sink, so we're concentrating on how the tap connects connects to the sink. Whether there is no running water, the bucket can be used in its traditional way (eg. taking water from the river). In the images you can see some of the clips we've been working on.

The table is a simple trestle construction. The table top is a scaled up version of a chopping board. We're realizing also a table cloth in glass-fiber that will be used for cooking instead of eating on it: the material characteristics make it perfect for using it as a base for the burner, to ensure a perfect isolation with the table surface. The measures will be around 80*120 cm and around 80 cm high. We'll discuss on the eventuality of having add-on wheels to the table legs, but we''d like to get the exact measures of the rails you're planning to build for the houses

If you think of using some of these products directly for the wet unit it's fine for us, but you'll have to keep in mind that, although working, they may not have the same kind of functionalities of traditional indoors equipments, because of the fact they're for an outdoor use and for the conceptual twist we decided to give them.

I'll post as soon as possible infos on the shelter. One of my colleagues that focused on the development of the shelter is at his job this morning. As soon as he'll get free we'll post you some material.

If you have any question don't hesitate to mail us or post questions on the blog!

Let's keep in touch for the monday conference,

All the best,

Hej då :)

Andrea & the Konstfack team.

Thursday, May 04, 2006

This fabric has been donated to us for the ICFF. It is part of the Sumbrella collection from Donghia. The fabric features colorfast quality, making it ideal for use outdoors in summer. Although the picture appears brown/tan, the actual fabric we are using is lighter.

Applications: outdoor tarp/overhanging. outdoor furniture, tensile structures on deck.

Wednesday, May 03, 2006

The workshop in Stockholm

This is the workshop that you will have access to during the prefabrication week in Stockholm. I am trying to book an additional studio as well for assembly check etc.

The gentleman on the picture is Jan Andersson, the technician that will help you. You can reach him at +46 8 450 41 95 or jan.andersson@konstfack.se

This is the machinery that will be available. There will also be some smaller hand machines like drills and saws.

All Best,

/Teo

The House that Parson's Built

Here is the house that we constructed before we were kicked out of the gallery April 21st. This is pretty much how it will look at the ICFF, except at the ICFF, we plan on having graphics on the exterior, and a flip book that really enhances the speed of our construction process. Right now we are focusing on improvements on construction and we are developing ideas for the interiors. Also, St. Etienne and Konstfack, we haven't heard from you in a while and we'd like to know if you have any more questions about measurements and meeting points and such.